Investigations on Glulam with Natural-Based Adhesive

The thesis analyses the effects of ageing and installation on the load-bearing capacity of natural-based adhesives on glued laminated timber.

Motivation

The energy transition and the declared goal of climate neutrality must also be accompanied by changes in the construction industry. The focus here is on the use of resource-saving building materials. As a renewable raw material, wood offers a wide range of possible uses. In view of the ever-increasing demand for natural materials, board stack elements, for example, can already make a contribution to producing low-emission constructions. Natural adhesives such as casein glue were also used at the beginning of glulam production. In order to test their possible use in today's constructions, the load-bearing behaviour of glulam beams manufactured at the beginning of the 20th century will be examined below.

The task

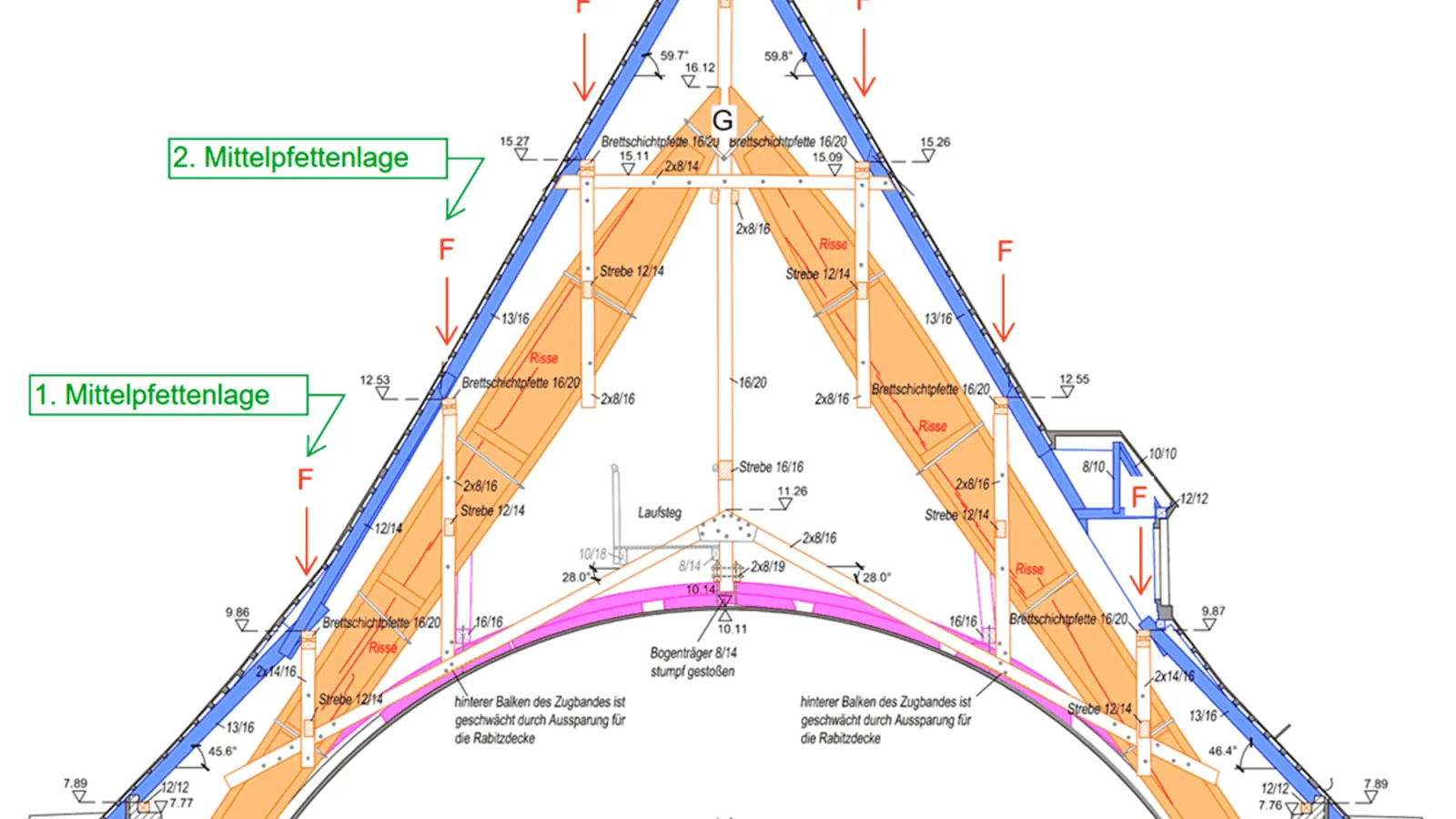

Thirteen beams from a building erected in 1913 were available for the evaluation of historical glulam (see Fig. 1). The analysed beams were manufactured using the Hetzer construction method at the time of construction. Additional test specimens were produced from sections of the beams not required for the 4-point bending tests. These were used to determine the compressive strength in the fibre direction, the shear strength of the glued joints, the bulk density and the moisture content. The task also included chemically analysing the type of glue used for bonding and microscopically determining the type of wood used. Following the 4-point bending tests, the results were to be used to assess the load-bearing capacity with regard to the original use as centre purlins.

Results

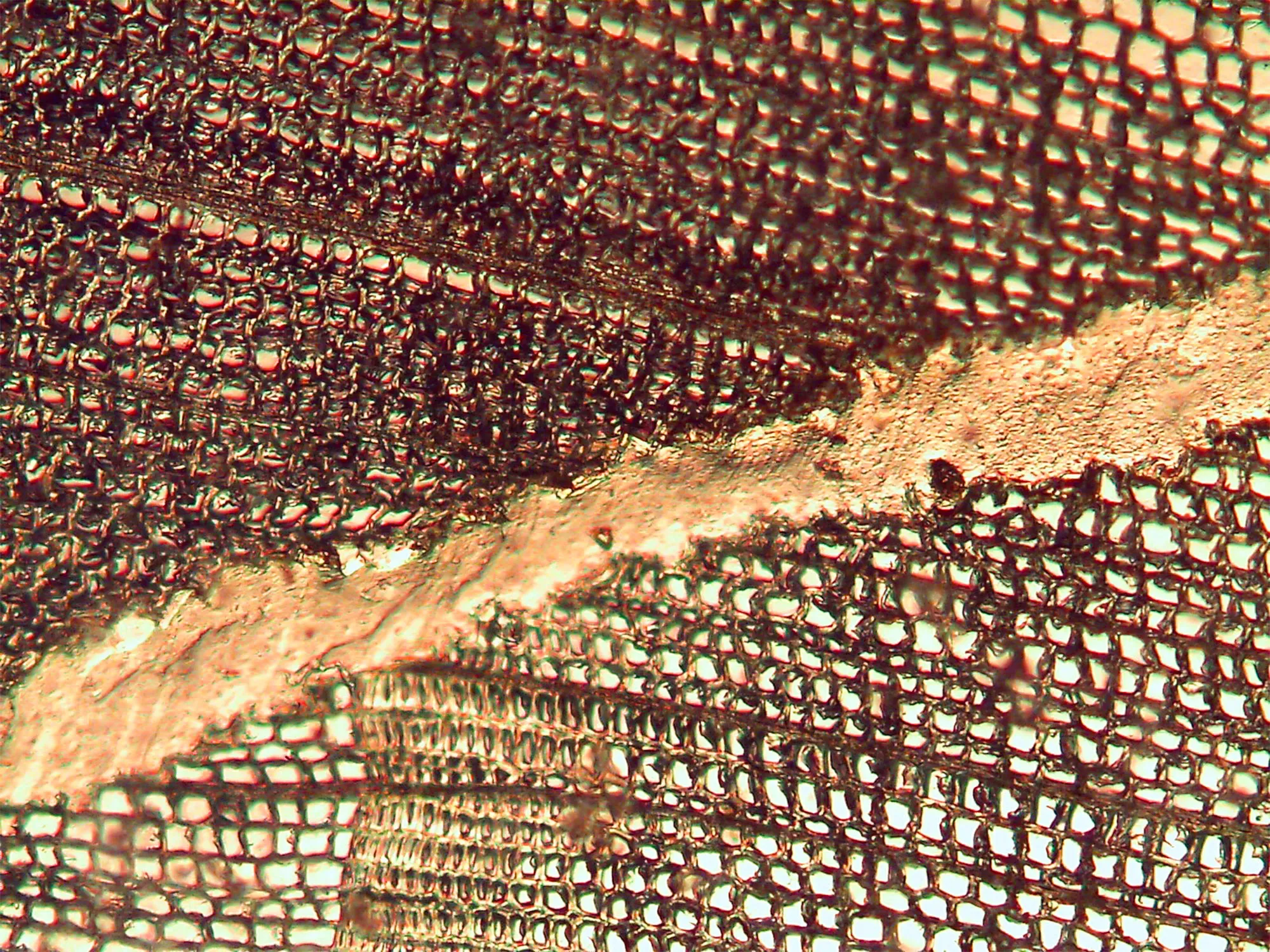

At the time the beams were delivered to the Potsdam University of Applied Sciences, they were in an overall poor condition. On the one hand, this condition was due to the unprotected storage of the beams immediately after removal (very rainy at the time) and, on the other hand, to the fact that they had been stored outdoors under simple tarpaulins for several years. During storage under the tarpaulins, holes in them and shifting of the tarpaulins repeatedly caused the beams to become damp and water to accumulate. In particular, the horizontal storage method of the beams led to partial water accumulation on the web due to the I-cross-section, as direct drainage through the top and bottom chords was hindered. This is reflected in the determined shear strengths of the glued joints, which show an average value of fv = 6.315 N/mm² between the bottom flange (L3/web) and web as well as the top flange and web. In contrast, an average value of fv = 8.67 N/mm² was determined for the shear strength of the glued joints between each other (L1/L2 and L2/L3). The stiffness properties with regard to the determined modulus of elasticity must also be assessed as too low. Spruce and fir wood generally has a modulus of elasticity of 11,000 N/mm² according to [DIN 68364, 2003]. The calculated modulus of elasticity has an average value of E ≈ 7,849 N/mm². The reduced stiffness of the beams indicates a shear-soft or damaged connection between the individual beam elements. The low bending strengths determined by the 4-point bending test can therefore also be partly attributed to the pre-damage (premature failure in shear). The beam geometry must also be considered when analysing the shear failure. This aspect can be analysed in more detail using the finite element method, for example. The values of compressive strength and bulk density correspond to the specifications of DIN 68364 [DIN 68364, 2003] for spruce and fir wood. The microscopic examination of thin-section specimens also confirms the use of spruce wood. However, as not all beams were analysed in this way, the presence of fir wood cannot be ruled out. Both types of wood have the same strength properties. Furthermore, they show that the wood structure has not yet been damaged by wood-destroying fungi. In the case of the processed support components (lamella, webs and top chords), it can be seen that in some cases large knots or knot accumulations were found in unfavourable areas (occurring tensile stresses). The type of glue used for bonding was narrowed down to a protein-based glue through chemical analyses. These usually consist of glutin or casein. Further investigations suggest that a casein glue was used to manufacture the Hetzer carriers. Finally, the beams could not be assigned to any standardised strength class. The service life of over 100 years and the fact that none of the centre purlins apparently had to be reinforced or replaced testify to the adequate design of the beams and the strength of the glue used.

Project participants

1st reviewer

2nd reviewer

Prof. (retired) Dr Wolfgang Rug

Master's graduate

Tommy Börner

Participants

- Dr. Gunter Linke

- Dipl. Chem. Christine Fuchs

- Dipl.-Rest. Jörg Weber

- Dipl.-Ing. (FH), Andreas Schultz, M. Sc,

- Marco Sieg

- Felix Zöllner

- Werner carpentry, Gadegast