BICENTENNIAL CAMD.COM [S]

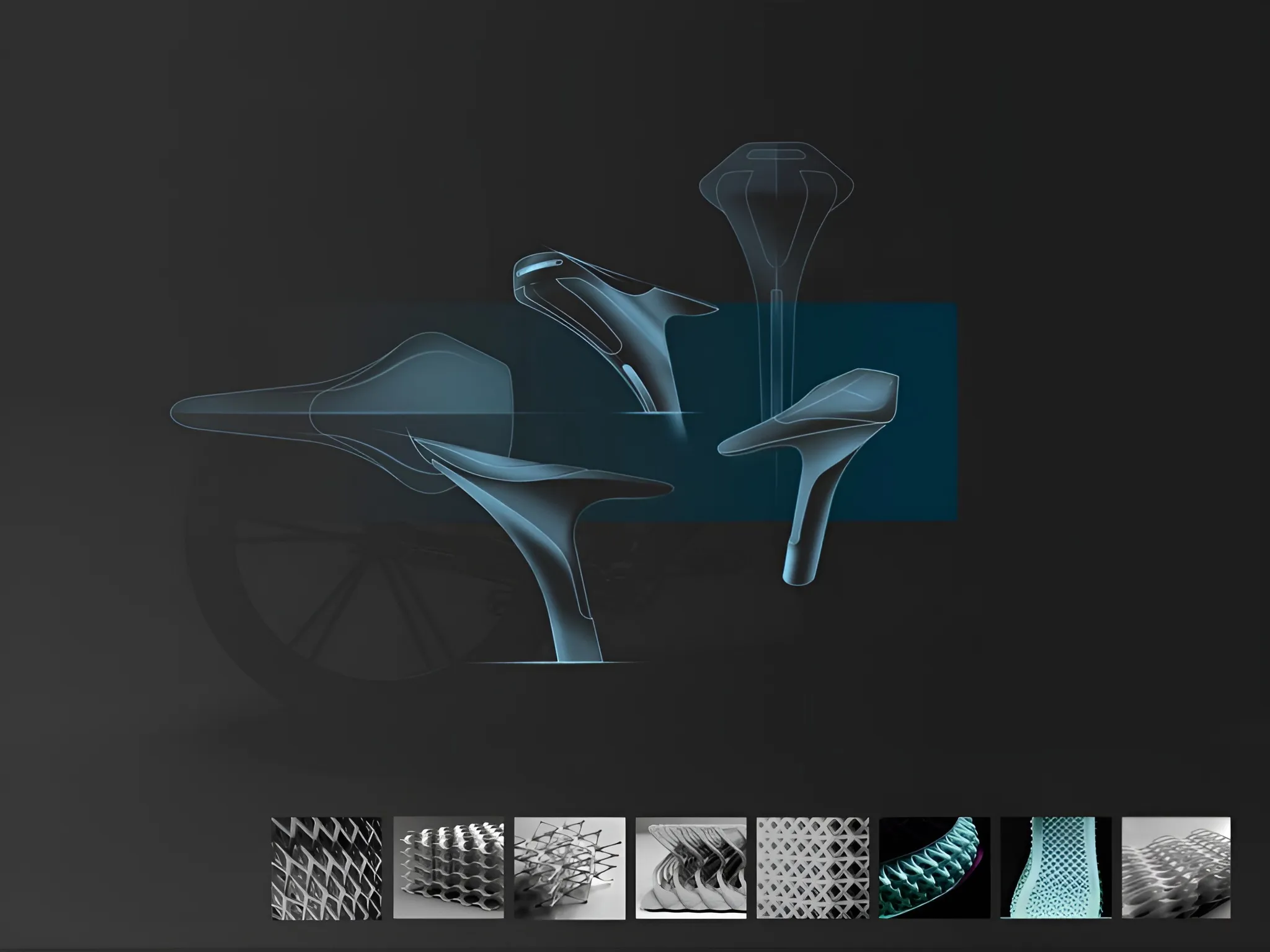

Additive manufacturing in the product design of user-specific bicycle components using the example of a bicycle saddle.

trinckle 3D GmbH

Grimmstr. 12 C

10967 Berlin

Germany

Additive manufacturing is a computer-aided manufacturing technology based on formless material. The significant difference to other CAD-based manufacturing processes is that a component is created without the use of semi-finished products and tools and is therefore not abrasive, but generative, or additive. This enables designers to create objects with a higher degree of complexity and free shaping.

The extended design freedom and the technology field are the foundation of this work. The attributes that are taken into account to varying degrees are, on a constructive level, function integration, function transformation and component reduction. At the user-specific level, individualisation mechanisms are integrated. The design thinking methods used for this are mass customisation, human-centred design and design automation. The seat component group presented is based on the consolidated relevance and feasibility with regard to the degree of individualisation and ergonomics under the personal aspect of time feasibility.

Master's thesis by Danny Giebitz

Supervision:

Prof. Jörg Hundertpfund & Prof. Dr. Frank Heidmann / Johannes Cremer as substitute